Forklift Automation

Forklift systems are an integral part of material handling and inventory management operations. However, the majority of the forklifts relies solely upon operator-initiated data collection methods to record all material movement transactions via keyed entry systems.

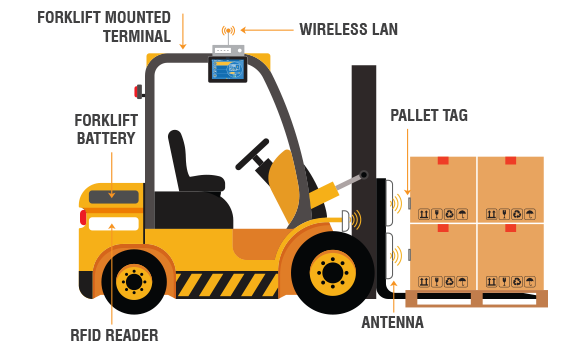

Developed on i-TEK’s warehouse management platform, i-TEK’s sensor-based RFID Forklift system, utilizes sensor, front installed antenna and IoT Gateway to identify an RFID pallet tag after it has been loaded onto the forklift. The System then identifies a pallet storage location, utilizing a bottom antenna, and IoT Gateway logic to confirm that the specific pallet has been picked up or dropped off at that location. These transactions are then sent to i-TEK’s cloud-based platform via Wi-Fi connectivity.